Sound Absorber Reapor®

Product Characteristics

Reapor® does not contain binders; there are no VOCs to be released and no break down over time. No smoke or volatiles are released when exposed to fire or flames. With no organic substances for bacteria to live on, Reapor® does not support mould growth. Reapor® resists weather, water, UV exposure and is resistant to chlorides and potassium.

Product Applications

Reapor® can be used as sound absorber in numerous demanding applications such as tunnels, noise barriers, industries, ceilings, enclosures, garages, fire safety areas etc.

Reapor® is available in various colors, making it aesthetically adaptable and easy to integrate into diverse architectural designs.

Installation

Reapor® panels can be cut and drilled using standard woodworking tools enabling easy installation. Reapor® panels are bonded into place using a special adhesive that maintains the panels’ non-combustible characteristics. The adhesive provides a permanent bond between the panels and a variety of common substrates.

The REAPOR installation manual is available for download further down on this page.

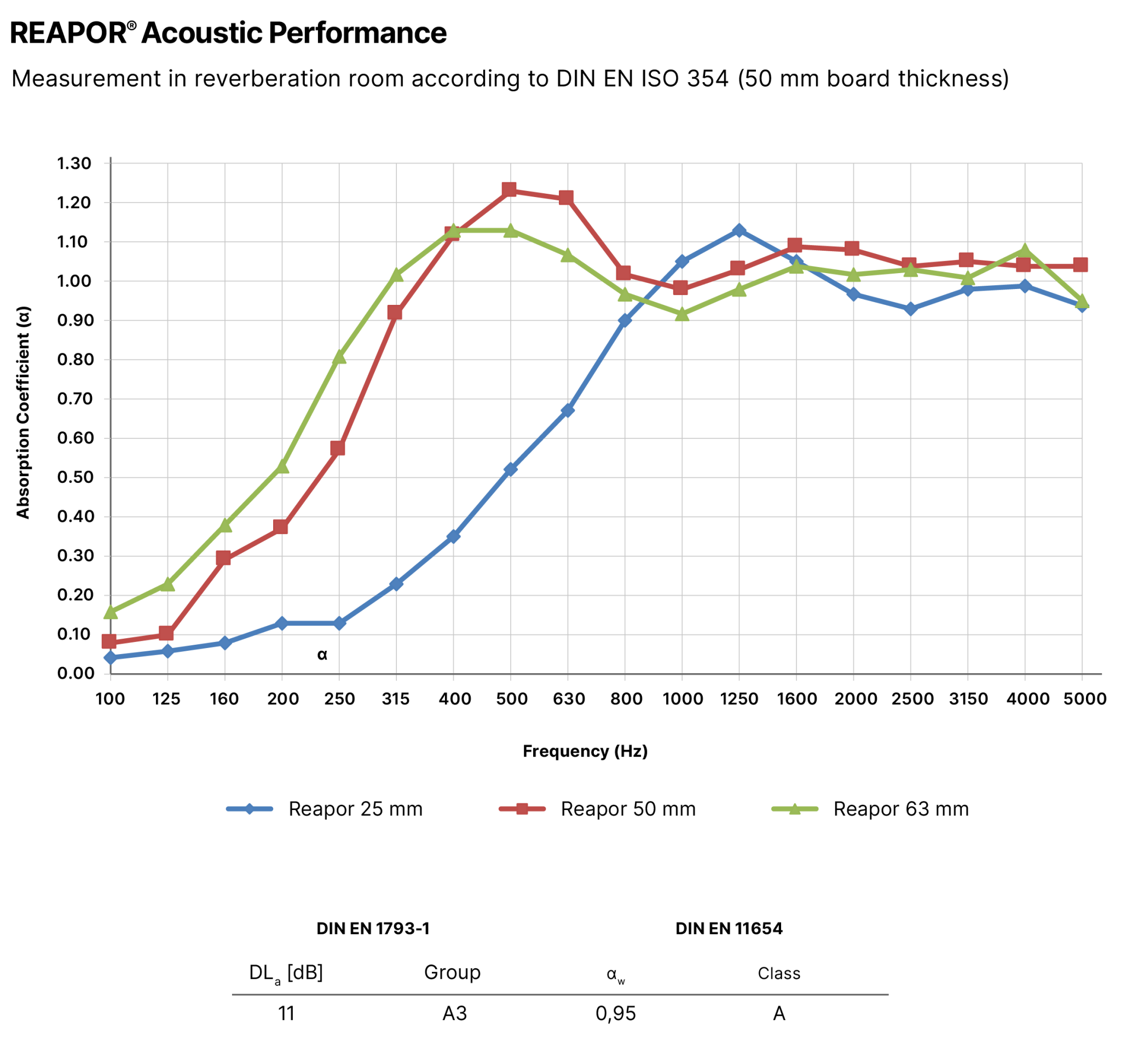

Technical Specifications

Sound absorber Reapor - Technical Specificationssound-absorber-reapor-technical-specifications.xlsx

Properties

| Product | Thickness (mm) | Panel size | Density (kg/m3) | ||

| Length | Width | Weight | |||

| (mm) | (mm) | (kg) | |||

| Reapor® 25/625625 | 25 | 625 | 625 | ≈ 2.6 | 270 |

| Reapor® 25/1200625 | 1200 | ≈ 5.1 | |||

| Reapor® 50/625625 | 50 | 625 | ≈ 5.3 | ||

| Reapor® 50/1200625 | 1200 | ≈ 10.5 | |||

| Reapor® 63/625625 | 63 | 625 | ≈ 6.6 | ||

Specification

| Test regulations | |||

| Bulk density | [kg/m³] | 260 ± 20 | |

| Compressive strength | [N/mm²] DIN | ≥ 1,2 | EN 196-1 |

| Bending tensile strength | [N/mm²] | ≥ 0,4 | DIN EN 196-1 |

| Thermal conductivity | 10tr [W/mK] | 0,08 | DIN 52612 |

| Length-specific flow resistance | [kPas/m²] | 10 - 20 | DIN EN 29053 |

| Fire resistance | A1 | DIN EN 13501-1 |

Downloads

REAPOR – installation manual | english

Fire behavior report – Reapor Fire Reaction A1